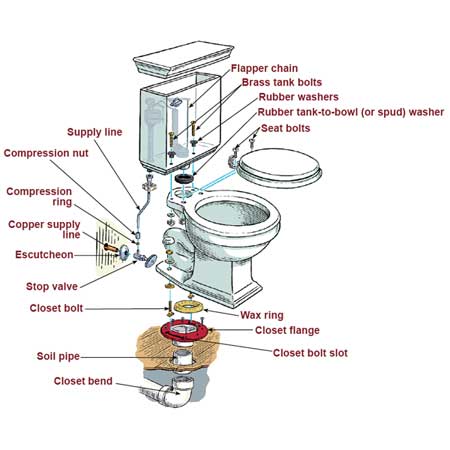

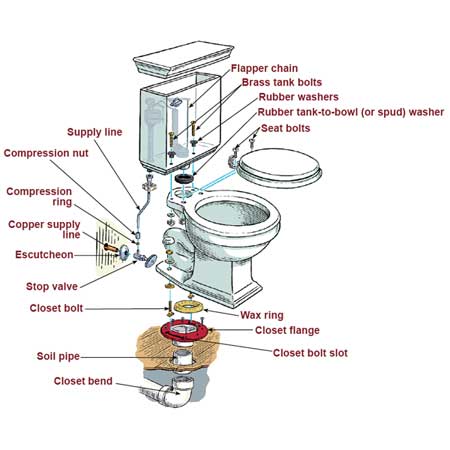

Illustration: Gregory Nemec

If your trusty toilet has developed cracks or leaks, uses

far too much water per flush, or is simply a shade of baby blue not seen in 20

years, it may be time to replace it. You might consider this a good time to put

in a call to the plumber, but it can be all in a day’s work for a reasonably

handy do-it-yourselfer. It’s not for the weak, since toilets are heavy and

unwieldy, but if you have a strong back (or a sturdy assistant) you can save

yourself the cost of a house call by installing it yourself.

Here, we asked This Old House plumbing and heating expert Richard

Trethewey to show how to install a new toilet. The time required varies, but

give yourself half a day if you’ve got a lot of experience with plumbing jobs,

and a full day if you’re a novice.

Stuff a rag into the soil pipe to block sewer gas and

prevent hardware from falling in.

Check that the hole in the floor is large enough to accommodate the closet

flange up to its collar. If the hole needs to be enlarged, trace around the

flange's base with a pencil, then cut away the excess flooring with a jigsaw.

Don’t cut any joists.

Dry-fit the soil pipe into the closet bend. Place the flange over the soil

pipe, then measure the gap between the bottom of the flange's collar and the

finish floor.

Remove the soil pipe and use a handsaw to trim it to the measurement in the

previous step. Remove burrs by scraping the cut edge with a utility knife.

Dry-fit the flange to the soil pipe, and the soil pipe to the closet bend to

ensure the flange's collar rests on the floor.

Wipe PVC primer on the inside of the closet bend and on the

outside of one end of the soil pipe. Apply PVC cement to those same surfaces

and immediately twist the soil pipe into the closet bend.

Prime and apply cement to the free end of the soil pipe and the inside of the

closet flange. Twist and press the flange onto the soil pipe until the collar

is seated on the floor.

Rotate the collar until its slots are positioned to the right and left of the

hole. (The closet bolts, which will be inserted into the slots, must line up

parallel to the wall behind the tank.)

Secure the collar to the floor with stainless steel screws long enough to bite

into the subfloor.

TIP: When gluing a fixed-collar PVC flange, align the bolt slots quickly

before the cement sets.

Shut off the bathroom's water-supply valve.

Place a bucket beneath the supply line, then sever the line with a tubing

cutter. Leave about 1 inch of pipe to attach the stop valve and escutcheon.

Allow the pipe to drain.

Remove the valve's handle and stem. (Heat from soldering may damage the stem's

plastic washers.)

Dry the pipe inside and out with a rag. Clean the inside and outside of the

pipe and the inside of the valve's inlet using a wire-brush pipe cleaner. Apply

flux to both areas.

Slip the escutcheon over the supply line, followed by the stop valve; the valve's

outlet should point upward.

Heat the supply line stop valve joint with a propane torch. Once the joint is

hot enough to melt the solder, remove the flame and run the solder around the

joint. When a drop of solder appears at the bottom, the joint is filled.

Insert the long brass closet bolts, threaded-end up, into

the flange collar's slots. Slip a brass washer over each.

Gently press the wax ring, flat-side down, over the flange.

Lift the toilet bowl over the flange, align the holes in its base with the

closet bolts, and lower the base onto the ring.

Without twisting or rocking, press the bowl down onto the wax ring until the

bowl's base rests on the floor. If the floor is uneven, shim the bowl with

stainless steel washers.

Slip a nylon washer over each bolt, then hand-thread the nuts. Tighten the nuts

with a wrench one quarter turn at a time, alternating between the two. Stop

when the wrench meets firm resistance; overtightening will crack the bowl.

With a hacksaw, trim the closet bolts at a point two threads above the top of

the nut. Snap the plastic bolt covers into place.

*Begin with this step is replacing an existing toilet or a faulty wax seal.

Make sure the large-diameter rubber tank-to-bowl (or spud)

washer on the outside of the tank's bottom is firmly seated.

Fit the small-diameter rubber tank washers into the small tank holes from the

inside of the tank, then insert the tank bolts.

Gently lower the tank onto the back of the bowl, guiding the ends of the tank

bolts into the holes.

Slip a nylon washer onto each bolt, then hand-thread the nuts.

Holding each bolt head in place with a screwdriver, hand-tighten the nuts,

alternating from nut to nut and checking repeatedly to make sure the tank is

level. Overtightening will crack the porcelain.

Connect the tank's handle to the flapper chain.

Using a tubing bender, curve the supply line to fit between

the stop-valve outlet and the tank-supply fitting. Then hold the pipe,

flared-end-up, between these two points and mark it half an inch below the

outlet. This will leave enough line to sit inside the outlet.

Cut the supply line at the mark made above, using a tubing cutter.

Slip the plastic nut, compression nut, and compression ring (in that order)

onto the supply line. Add a thin coat of Teflon paste to the valve's outlet

threads, then seat the line in the outlet, and fit the compression ring.

Hand-tighten the supply line's plastic nut under the tank. Then tighten the

compression nut with a wrench

Position the seat assembly over the bowl, then insert the

plastic bolts through the seat back and the bowl's seat holes; tighten the nuts

by hand.

Turn on the main supply line, open the stop valve, and allow the tank to fill.

Flush six times. Check for leaks.

by Scott Gibson